I am dripping a lot of transmission oil out of the slot (weep hole?) at the bottom of the bell housing where the trans meets the engine. I’m sure it it transmission oil because it is red (MTL) and my engine oil is green (Brad Penn). Plus, the engine oil isn’t low, but the transmission is losing oil at an alarming rate. I checked the transmission oil level before going to the track this weekend and it was WAY down. I checked it again Sunday morning and had to add a fair amount of oil after just one day.

It apparently comes out more when driving, which makes sense, but also drips slightly when the car is parked, which doesn’t (if the input shaft opening is higher than the oil level).

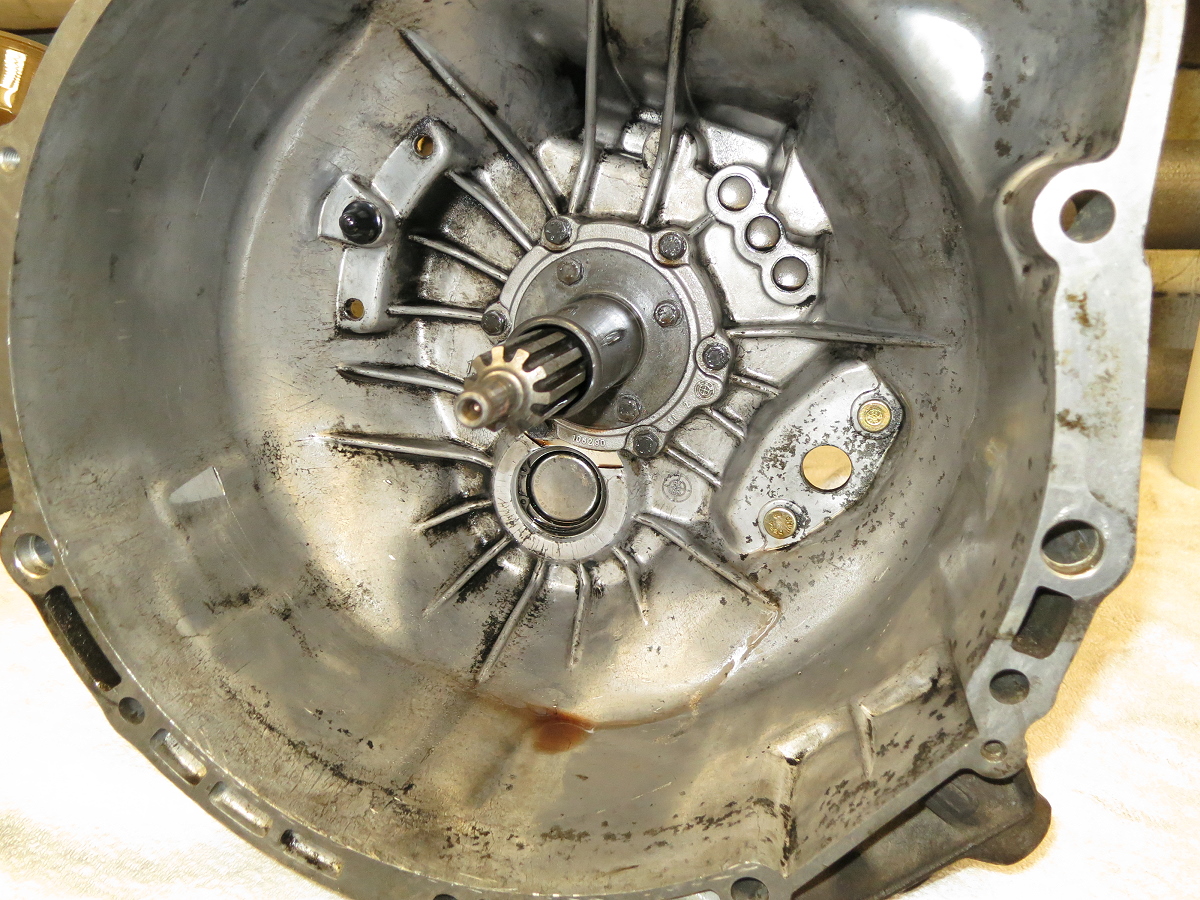

I pulled the engine and trans and I replaced all the seals on both after buying the car. Due to unclear instructions in the Bentley manual, I may have buggered up the housing that the input shaft seal fits into. I tried to sand off any rough spots I caused, but may not have done it well enough. I suppose it is also possible that I didn’t get the seal installed correctly. Either way, I’m afraid I will need to drop the transmission and try to reinstall the seal.

Before I do that, I thought I’d see if anybody knows whether there is another source the trans oil could be coming from? As far as I recall, the input shaft is the only opening in the front of the transmission. But, the fact that it was leaking there before I replaced the seals makes me wonder if there might be something else going on.

Any ideas?

And I will most probably do it in the near future.

And I will most probably do it in the near future.

) I have always double-checked that the crank rear seal was leaking (since I know it is a common problem).

) I have always double-checked that the crank rear seal was leaking (since I know it is a common problem).